1. PRIMI PASSI

Congratulazioni per aver acquistato l'affilacoltelli ELITE CU mini 1200.

Si prega di leggere questa guida prima di iniziare.

Il modello ELITE CU mini 1200 è una macchina industriale per l'affilatura e la rettifica delle lame, che consente di ottenere la massima qualità per il lavoro a cui è destinata. La sua progettazione e programmazione consentono di ottimizzare il lavoro di affilatura in modo agile e sicuro.

È possibile visualizzare il catalogo prodotti al seguente link: Modello ELITE CU mini 1200

Questo manuale vi presenta le principali funzioni della macchina affilatrice per evitare rischi per la vostra salute o che potrebbero causare guasti o usura prematura della macchina.

In caso di dubbi, contattateci direttamente o rivolgetevi a uno dei nostri distributori autorizzati.

Nota informativa: L'uso descritto nel manuale di questo affilacoltelli in esso descritto può presentare alcune variazioni nell'uso poiché i nostri macchinari sono soggetti a possibili modifiche costruttive, in funzione dell'incorporazione di progressi tecnologici nelle nostre attrezzature di affilatura.

2. SICUREZZA

2.1.Regole di sicurezza

Rispettare e applicare attentamente le seguenti norme di sicurezza; la mancata osservanza di tali norme può causare lesioni personali o danni alla macchina stessa.

L'installazione e la manutenzione della macchina descritta nel presente manuale devono essere eseguite esclusivamente da operatori che ne conoscano il funzionamento e che siano in possesso di sufficienti conoscenze tecniche.

Il modello ELITE CU mini 1200 è stato progettato per l'affilatura delle lame, escludendo qualsiasi altro tipo di operazione.

PERICOLO DI ALTA TENSIONE

PERICOLO DI INCIDENTE

PERICOLO DA PROIEZIONE DI SCINTILLE

USARE SCARPE PROTETTIVE

PERICOLO DA UTENSILI AFFILATI

USARE PROTEZIONI PER L'UDITO

Le presenti avvertenze non includono tutti i possibili rischi che potrebbero derivare da un uso improprio della macchina. Pertanto l'operatore deve procedere con cautela e nel rispetto delle regole.

2.2.Utilizzo e conservazione del manuale di istruzioni

Il presente manuale di istruzioni deve essere letto e compreso da tutto il personale che entra in contatto con la macchina.

Questo manuale è per:

- Indicare il corretto utilizzo della macchina in base al tipo di lavoro da svolgere.

- Fornire le istruzioni necessarie per il trasporto, la regolazione e la manutenzione della macchina.

- Facilitare l'ordinazione dei pezzi di ricambio e le informazioni sui rischi.

Limiti di utilizzo del manuale:

La macchina è destinata all'uso professionale e pertanto l'esperienza dell'operatore è necessaria e di vitale importanza.

Importanza e conservazione del manuale:

Il presente manuale deve essere considerato parte integrante della macchina e pertanto dovrà accompagnarla fino al termine del suo utilizzo.

Ulteriori informazioni e chiarimenti:

L'utilizzatore, il proprietario o il manutentore possono rivolgersi al costruttore per richiedere qualsiasi informazione aggiuntiva sull'uso della macchina e sulle possibili modalità di intervento di manutenzione e riparazione.

Scadenza della responsabilità:

Il produttore è esonerato da ogni responsabilità in caso di:

- Uso improprio della macchina

- Utilizzo della macchina da parte di persone non addestrate

- Gravi guasti nella manutenzione programmata

- Interventi o modifiche non autorizzati

- Utilizzo di ricambi non originali.

2.3.Dichiarazione di conformità

Con la presente la società:

Elite Machines, SLU

Joan Oró, 27

ES-08635 Sant Esteve Sesrovires

dichiara che il prodotto di seguito indicato, in base alla sua progettazione e costruzione, nonché nella versione immessa sul mercato dalla nostra azienda, è conforme ai requisiti essenziali obbligatori di salute e sicurezza della direttiva CE.

La presente dichiarazione perde la sua validità in caso di modifiche non autorizzate al prodotto.

Nome del prodotto: ELITE CU mini 1200

Tipo di prodotto: macchina per affilatura e rettifica di lame industriali

Numero di serie: __

Competenze di gestione CE:

- Direttiva Macchine CE (2006/42/CE)

- Direttiva Europea sulla compatibilità elettromagnetica (2014/30/UE)

- Gli scopi di protezione della Direttiva CE sulla bassa tensione (2006/95/CE) sono stati soddisfatti in conformità all'allegato I, n. 1.5.1 della Direttiva Macchine 2006/42/CE

La documentazione tecnica è stata redatta dal Rappresentante legale della documentazione:

Sergi Valls Gramunt

Joan Oró, 27

ES-08635 Sant Esteve Sesrovires

Data / produttore - Firma: __

Dettagli del firmatario: Sergi Valls Gramunt, manager

3.DATI TECNICI

Nella seguente tabella informativa troverete l'elenco delle specifiche tecniche della macchina descritta nel presente manuale.

| CARATTERISTICHE TECNICHE | |

|---|---|

| Capacità lavorativa utile | Fino a 1230 mm. |

| Potenza motore mola | 3 HP per la versione a 50 Hz. 4 HP per la versione a 60 Hz. Opzionale: 4 HP nella versione a 50 Hz / 5 HP nella versione a 60 Hz |

| Diametro mola | 150 mm. |

| Mandrino magnetico | Dimensioni: 1230 x 100 mm. |

| Movimentazione carrello motorizzata | Movimento su guide lineari e traslazione tramite ruota. |

| Rotazione della piastra | Da 0º a +90º. |

| Pannello di controllo | Con schermo LCD con memorizzazione dei programmi. |

| Abbassamento automatico e programmabile della mola abrasiva | Utilizzo di guide con cuscinetti antifrizione, smorzatori di vibrazioni e mandrino trapezoidale. |

| Attrezzature di refrigerazione | Capacità 70 litri |

| Connessione | 400 V. 50 Hz. 3 fasi + N / 230 V. 50/60 Hz. 3 fasi |

| Consumo di energia elettrica | Consumo massimo: 4 KW |

| VERSIONI DISPONIBILI | ||

|---|---|---|

| Modello | Dimensioni (mm.) | Peso (kg.) |

| ELITE CU mini 1200 | 2570 x 920 x 1840 | 540 |

3.1 REQUISITI TECNICI

Tensione di collegamento: 220/400 V 3Ph 50/60 Hz

Potenza di collegamento richiesta: 4 kW

3.2 ATTREZZATURA INCLUSA

- Piastra di serraggio magnetica 1230x100 mm.

- Distanza massima tra piastra e mola abrasiva: 95 mm.

- Piastra regolabile da 0º a 90º.

- Abbassamento automatico della mola

- Abbassamento parziale regolabile da 0,01 mm a 0,5 mm. Regolabile in modo continuo.

- Discesa totale regolabile da 0 a 5 mm. Regolabile in modo continuo.

- Programma di produzione per l'affilatura di lame della stessa dimensione.

- Motore della mola da 3 CV. (4 CV nella versione 60 Hz). Opzionale: motore da 4 CV

- Mola abrasiva ø150 mm.

- Pannello di controllo facile da usare con touch screen LCD

- Attrezzatura frigorifera con capacità di 70 litri

- Predisposto per il collegamento ad un sistema di filtrazione centralizzato ELITE modello FILTRAmaq SOLO/PRO.

- Spostamento del carrello motorizzato

- Variatore di velocità dell'auto

- Regolazione della lunghezza di lavoro

- Movimento di discesa della mola tramite guide con cuscinetti antivibranti.

4. TRASPORTO

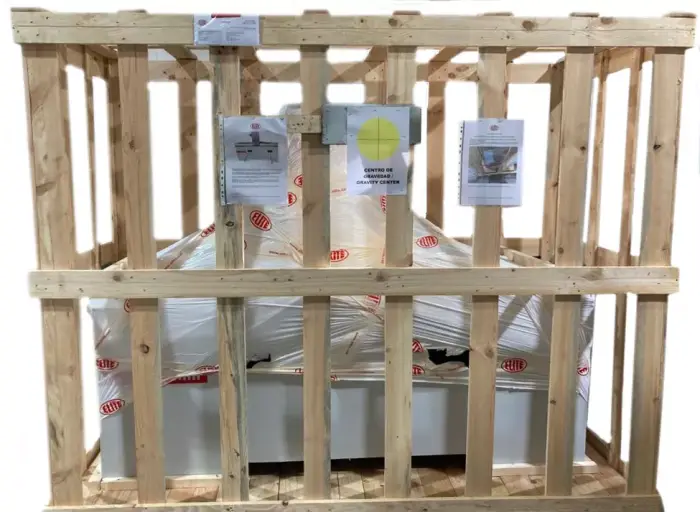

Il modello ELITE CU mini 1200 viene consegnato imballato su pallet, cassa o cassa di legno. A seconda della destinazione e del mezzo di trasporto.

Durante tutti i trasporti e gli spostamenti, la macchina deve essere mantenuta nella sua posizione verticale originale; qualsiasi variazione di questa posizione può comportare la perdita della garanzia.

| Modello macchina | Dimensioni (mm) | Peso (kg) |

|---|---|---|

| ELITE CU mini 1200 | Dimensioni: 2200 x 650 x 1500 | 540 |

4.1.Istruzioni per il disimballaggio e il montaggio

Prestare particolare attenzione durante il sollevamento del carico: il carico non deve essere centrato! Per fare ciò, utilizzare un carrello elevatore con pale sufficientemente lunghe da sostenere la macchina, tenendo conto della larghezza e della profondità della macchina nel calcolo dei pesi da sollevare.

Una volta aperta la confezione, rimuovere i fermi di fissaggio dai piedini della macchina.

Per estrarre la macchina dall'imballaggio, utilizzare esclusivamente un carrello elevatore dotato di lame sufficientemente lunghe per sostenerla adeguatamente.

Assicurarsi di sollevare la macchina inserendo le lame del carrello elevatore nei due fori appositamente predisposti su ciascun lato della macchina.

Per ottenere una maggiore stabilità, le lame devono rimanere aperte il più possibile, per quanto lo spazio della macchina lo consenta.

PERICOLO DI RIBALTAMENTO DELLA MACCHINA SE NON MANEGGIATA CON CURA. EVITARE FRENATE O MOVIMENTI IMPROVVISI!

Una volta che la macchina è nella sua posizione definitiva, è possibile rimuovere la pellicola protettiva e le altre protezioni dai componenti che fissano e impediscono al carrello di muoversi.

5. INSTALLAZIONE

5.1.Posizionamento della macchina

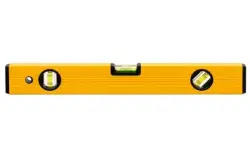

Prima di qualsiasi lavoro, bisogna assicurarsi che la macchina sia ben allineata e che non oscilli in nessuna delle sue estremità, nel qual caso deve essere bloccata per impedirne il movimento. Per ottenere il livello corretto è necessario utilizzare una livella a bolla. Questo controllo deve essere effettuato sia longitudinalmente che trasversalmente.

Un livellamento non corretto della macchina può causare vibrazioni indesiderate e un'usura prematura delle guide lineari.

ATTENZIONE: La macchina non deve essere utilizzata in nessun caso da personale non qualificato o non autorizzato.

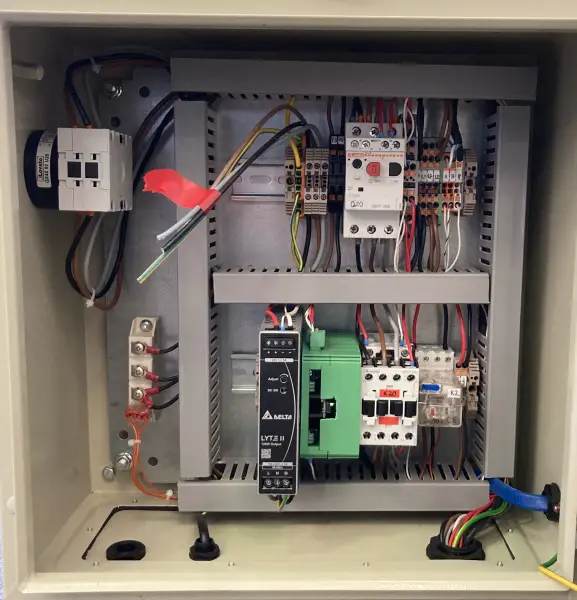

5.2.Collegamento elettrico

PERICOLO DI ALTA TENSIONE!

Da ricordare: prima di collegare la macchina accertarsi delle protezioni di cui la macchina può avvalersi per proteggere i componenti durante il trasporto.

L'affilatrice ELITE modello CU mini 1200 deve essere collegata rigorosamente alla tensione indicata sull'ordine della macchina e sulla macchina stessa. Il collegamento ad una tensione diversa da quella indicata può provocare guasti alla macchina e rappresentare un rischio per le persone che la utilizzano.

Questa installazione deve essere eseguita da personale tecnico qualificato e verificata con un voltmetro prima di accendere la macchina.

È assolutamente indispensabile che la sezione del cavo di collegamento sia quella richiesta, che la macchina abbia una presa di corrente specifica e sia protetta da sovraccarichi e derivazioni e che sia il più vicino possibile alla presa di corrente.

I terminali di collegamento elettrico sono dotati di nastro rosso per facilitare il corretto collegamento.

ELITE non si assume alcuna responsabilità in caso di installazione elettrica non corretta che possa causare malfunzionamenti della macchina e persino danni a persone o cose.

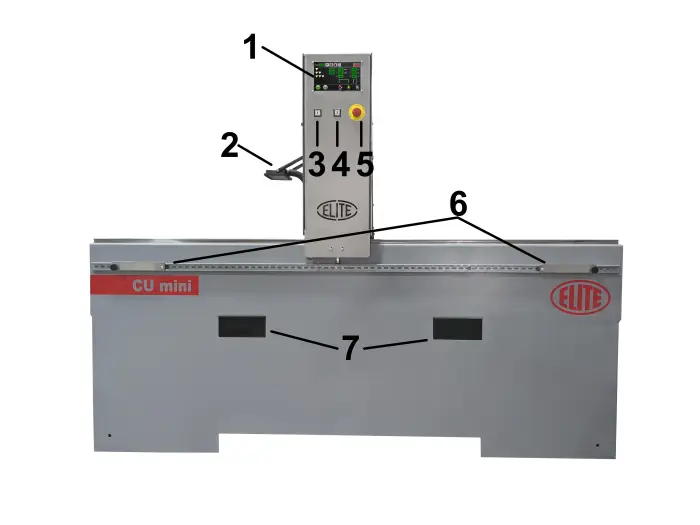

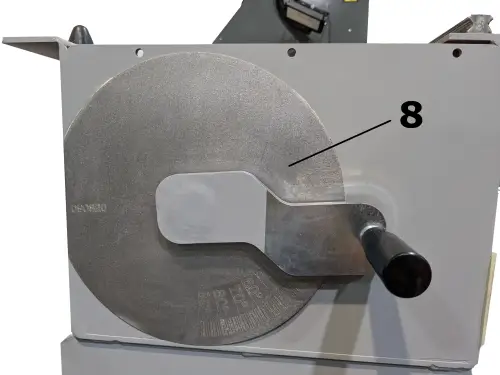

5.3.Componenti principali della macchina

1.Schermo

2.Luce LED

3.Pulsante di sollevamento della mola

4.Pulsante di abbassamento della mola

- Arresto di emergenza

- Regolatori di viaggio della carrozza

- Fori per il sollevamento della macchina

- Leva di selezione del grado della piastra

6. AVVIAMENTO

In questa sezione ti mostreremo come utilizzare al meglio ELITE CU mini 1200.

NOTA: I dati mostrati nelle diverse immagini sono solo a scopo esemplificativo. Ogni tipo di strumento ha i suoi dati consigliati e un operatore esperto deve conoscerli.

Arresto di emergenza

È il pulsante rosso rotondo. In caso di guasto durante l'uso o di creazione di una situazione di pericolo, consente la disconnessione immediata della macchina.

Non deve essere utilizzato se non strettamente necessario.

Una volta utilizzata, per riutilizzare la macchina è necessario riportarla nella posizione iniziale. Sono necessari ulteriori riferimenti e impostazioni.

ATTENZIONE: Non modificare o manomettere in nessun caso questo comando, poiché ciò mette automaticamente a rischio di gravi lesioni l'operatore e le persone che gli stanno intorno.

Operazione di affilatura

Per avviare il processo di affilatura, è necessario innanzitutto assicurarsi che il pulsante di arresto di emergenza non sia attivato.

PERICOLO: Non azionare mai i pulsanti del pannello di controllo durante la sostituzione della mola abrasiva: rischio di lesioni molto gravi. Si raccomanda vivamente di spegnere la macchina e di scollegarla dalla rete elettrica quando si lavora al suo interno.

ATTENZIONE: prima di iniziare a far girare la mola, assicurarsi che questa sia fissata saldamente al portamola in cui è posizionata e che NESSUNO stia manomettendo la zona in cui gira. IN NESSUN CASO LA RUOTA DEVE ESSERE TOLATA MENTRE QUALCUNO LA STA MANEGGEVOLMENTE.

6.1.Avviamento

6.2. Sostituzione della mola abrasiva

Attrezzi necessari: chiave inglese n. 17.

Con la macchina spenta, rimuovere la vite esagonale dalla parte inferiore della mola abrasiva. Tenere ferma la mola abrasiva e l'anello portamola in modo che non cadano.

Ora inserisci la nuova mola.

Riposizionare l'anello di posizionamento nella posizione corretta in modo che il perno di posizionamento passi attraverso l'anello di posizionamento.

Riposizionare il bullone esagonale e serrarlo.

6.3 Montaggio della corona porta segmento

6.4. Come posizionare le lame per l'affilatura

7. FUNZIONE DI LAVORO

7.1. Pannello di controllo

7.2. Come smagnetizzare lame e utensili.

Se le lame o gli utensili vengono magnetizzati dalle piastre magnetiche, possiamo utilizzare lo smagnetizzatore ELITE per rimuovere i residui (accessorio opzionale).

7.3. Come modificare i segmenti del supporto del segmento

8. MANUTENZIONE

8.1.Manutenzione preventiva

La manutenzione del modello ELITE CU mini 1200 è molto semplice ma allo stesso tempo importante.

Si compone di quanto segue:

- Pulizia delle guide del carrello - Giornaliera

- Se la macchina non viene utilizzata per diversi giorni, pulire e ingrassare la piastra per evitare la formazione di ruggine.

- Controllare il livello del liquido di raffreddamento nel serbatoio, utilizzando il liquido di raffreddamento consigliato da ELITE: SintoCut MIX per acciaio ed ELITE SintoCut PRO MIX per acciaio + carburo di tungsteno. La miscela refrigerante deve essere realizzata con acqua in una proporzione compresa tra il 2 e l'8% di SintoCut. Al di sotto di questo livello si può verificare l'ossidazione delle parti meccaniche, mentre se il livello è superiore può essere tossico.

- Rimuovere i fanghi che si depositano sia nell'area di lavoro che nel liquido refrigerante - Quotidianamente.

- Ingrassare i cuscinetti scorrevoli del carrello utilizzando gli ingrassatori - Mensilmente.

- Mantenere la macchina pulita e in buone condizioni consentirà un utilizzo ottimale a lungo termine.

Utilizzare l'apparecchiatura solo in ambienti asciutti. La temperatura dovrebbe essere compresa tra 5 e 40ºC. Un'umidità relativa superiore al 90% e un ambiente salino causerebbero una corrosione prematura della macchina.

9. ACCESSORI E MATERIALI DI CONSUMO

9.1. Molari

9.1.1.Per affilatura pesante su lame in acciaio

Consigliamo di utilizzare il riferimento ELITE. numero 3522-A2 o 3522-B2. 6A2 Resina ø150x60xø60 mm.

9.1.2.Per HSS o piccole asportazioni di materiale su lamiere di acciaio

Consigliamo di utilizzare il riferimento ELITE. numero Italiano: 6A2 ø150x6x4x50xø24CH8 B181 C75

9.1.3.Per lame in carburo di tungsteno

Consigliamo di utilizzare il riferimento ELITE. numero 3020-A2. 6A2 ø150x6x4x50xø24CH8 D126 C75

9.2.Agenti di raffreddamento

9.2.1. Lavorare solo con acciaio e HSS

Si consiglia di utilizzare ELITE SintoCut MIX o un prodotto equivalente quando si lavora solo con l'acciaio.

9.2.2.Lavori con acciaio e carburo

Se la macchina deve lavorare sia con l'acciaio che con il carburo di tungsteno, allora è meglio lavorare con SintoCut PRO MIX o equivalente; lavorare con il carburo è un'opzione migliore.

9.3.Squadre

9.3.1.Sistemi di filtraggio

La macchina può essere dotata di uno dei seguenti sistemi di filtrazione ELITE. Se la tua macchina è già dotata di uno di questi sistemi e hai bisogno di informazioni o assistenza, consulta il manuale del sistema di filtraggio.

9.3.1.1.SOLO FILTRAmaq

Sistema di filtrazione indipendente per una macchina.

9.3.1.2.FILTRAmaq PRO

Sistema di filtrazione centralizzato per un massimo di 5 macchine.

9.4.Smagnetizzatore

Per lame o utensili che si magnetizzano, consigliamo di utilizzare lo smagnetizzatore ELITE.

10. GARANZIA

Tutte le nostre macchine vengono testate prima di essere spedite. Tuttavia, potrebbero sempre esserci difetti non visibili a occhio nudo.

Le nostre macchine sono garantite contro difetti di fabbricazione e di materiali in normali condizioni di utilizzo e manutenzione.

Il periodo di garanzia è di 12 mesi dalla data di acquisto e consiste nella sostituzione del materiale difettoso.

La garanzia decade automaticamente in caso di modifiche non imputabili alla nostra azienda. Oppure in casi evidenti di uso improprio della macchina.

La garanzia non comprende le parti soggette a normale usura dovuta all'uso, come pattini, cartucce di lubrificazione, abrasivi, ecc.

11.SCARICA IL MANUALE

12. DOMANDE FREQUENTI

Domanda nr1

Risposta no. 1