1. FIRST STEPS

Congratulations on your purchase of the ELITE SOLDAmaq HF high frequency generator welder.

Please read this guide before you begin.

ELITE SOLDAmaq HF is specially designed for the saw blade producer or grinding shop with high demands for saw blade tip repair.

You can view the product catalog at the following link: ELITE model SOLDAmaq 1200

This manual introduces you to the main functions of the welding machine in order to avoid risks to your health or that may cause breakdown or premature wear of the machine.

If you have any questions, please contact us directly or one of our authorized distributors.

Informative Note: The use described in the manual of this welder may present some variations in use since our machinery is subject to possible construction modifications, depending on the incorporation of technological advances in our welding equipment.

2. SECURITY

2.1.Safety rules

Observe and carefully apply the following safety rules. Failure to follow these rules may cause personal injury or damage to the machine itself.

Installation and maintenance of the machine described in this manual must be carried out only by operators who are familiar with its operation and have sufficient technical knowledge.

The ELITE SOLDAmaq HF welding machine has been designed for the repair of circular saws, excluding any other type of operation.

DANGER HIGH VOLTAGE

DANGER OF ACCIDENT

DANGER DUE TO SPARK PROJECTION

WEAR PROTECTIVE SHOES

DANGER FROM SHARP TOOLS

USE HEARING PROTECTORS

These warnings do not include all possible risks that improper use of the machine could cause. For this reason, the operator must proceed with prudence and observing the rules.

2.2.Use and storage of the instruction manual

This instruction manual must be read and understood by all personnel who come into contact with the machine.

This manual is for:

- Indicate the correct use of the machine according to the type of work to be carried out.

- Provide the necessary instructions for the transport, adjustment and maintenance of the machine.

- Facilitate the ordering of spare parts and information of risks.

Limits of use of the manual:

The machine is intended for professional use and therefore the experience of the operator is required and of vital importance.

Importance and conservation of the manual:

This manual must be considered part of the machine and must therefore be attached to it until the end of its use.

Additional information and clarifications:

The user, owner or maintenance person can contact the manufacturer to request any additional information on the use of the machine and possible modalities for maintenance and repair intervention.

Expiration of responsibility:

The manufacturer is considered exempt from any liability in the event of:

- Improper use of the machine

- Use of the machine by untrained persons

- Serious failures in scheduled maintenance

- Unauthorized interventions or modifications

- Use of non-original spare parts.

2.3.Declaration of conformity

The company hereby:

Elite Machines, SLU Joan Oró, 27

ES-08635 Sant Esteve Sesrovires

Declares that the product indicated below, based on its conception and construction, as well as the version put on the market by our company, complies with the mandatory basic health and safety requirements of the CE directive.

This declaration loses its validity in the event of unauthorized modifications to the product.

Product name: ELITE SOLDAmaq HF

Product type: High frequency generator welding machine

Serial No.: __

EC Directive Competences:

- EC Machinery Directive (2006/42/EC)

- European directive on electromagnetic compatibility (2014/30/EU)

- The protection purposes of the CE low voltage directive (2006/95/CE) were fulfilled according to annex I, nr. 1.5.1 of the machinery directive 2006/42/EC

The technical documentation was compiled by legal representative of the documentation:

Sergi Valls Gramunt

Joan Oró, 27

ES-08635 Sant Esteve Sesrovires

Date / manufacturer - Signature: __

Signatory data: Sergi Valls Gramunt, manager

3.TECHNICAL DATA

In the following information table, find the list of technical specifications of the welders described in this manual.

| TECHNICAL DATA | SOLDAmaq HF |

|---|---|

| Saw blade diameter | 150 to 850 mm (5.9" to 33.5") |

| Saw blade hole | 20 to 130 mm (0.78" to 5-1/9") |

| Welding angle | From -20 to +25º |

| Installed power | 4 kilowatts |

| AVAILABLE VERSIONS | ||

|---|---|---|

| Model | Packaging size | Gross weight |

| SOLDAmaq HF basic | 1600 x 1150 x 2070 mm. | 340 Kg. |

| SOLDAmaq HF with pyrometer | 1600 x 1150 x 2070 mm. | 370 Kg. |

4. TRANSPORTATION

The ELITE SOLDAmaq HF is delivered packed in a wooden box.

During all transportation and transfer, the machine must be kept in its original vertical position; any variation in this position may lead to the loss of the warranty.

| Model | Packaging size | Gross weight |

| SOLDAmaq HF basic | 1600 x 1150 x 2070 mm. | 340 Kg. |

| SOLDAmaq HF with pyrometer | 1600 x 1150 x 2070 mm. | 370 Kg. |

4.1.Unpacking and assembly instructions

Be especially careful when lifting the load: the load may not be centered!

To lift or move the load, use a forklift with blades long enough to support the machine, taking into account the width and depth of the machine when calculating the weights to be lifted.

To unpack, remove the front panel and any wooden locks or fixing screws from the base of the machine.

Once the machine has been moved to its final work destination, you must secure the machine to the ground using the 4 screws placed on the base support of the machine. If this is not done, there is a high risk of the machine falling and causing serious injury to personnel and the machine itself.

Once the machine is in its final location, the protective film and other component protections, which secure and prevent the machine from moving, can also be removed.

5.INSTALLATION

5.1.Placement of the machine

Before any work, make sure that the machine is well aligned and does not oscillate at any of its ends, in which case it must be chocked to prevent movement. For correct leveling it is necessary to use a leveling tool. This control must be carried out both longitudinally and transversely.

A poor leveling of the machine can cause unwanted vibrations and premature wear of the linear guides.

ATTENTION: The machine must not be used under any circumstances by unqualified or unauthorized personnel.

5.2.Electrical connection

DANGER HIGH VOLTAGE!

SOLDAmaq welding machines must be strictly connected to the voltage indicated in the machine order and on the machine itself. Connecting to a voltage other than that indicated may cause damage to the machine and represents a risk to the people who use it.

For connection to the electrical network, the machine only requires two phases and a ground connection.

This installation must be carried out by qualified technical personnel and checked with a voltmeter before turning on the machine.

ELITE Sharpening Machines, rejects all responsibility for a poor connection, which in addition to causing the machine to malfunction can damage people, animals, and material objects.

Remember: Before connecting the machine, remove any protections that the machine may have to protect the components during transport.

5.3. Cooling circuit water connection

The ELITE welding equipment model SOLDAmaq HF comes pre-wired with cooling tubes. You must check the coolant level upon receiving the welder and fill exclusively with water for the cooling circuit in the upper caps indicated for this purpose.

PERIODIC CHECKING OF THE COOLANT LEVEL IS ABSOLUTELY ESSENTIAL.

5.4.Main components of the machine

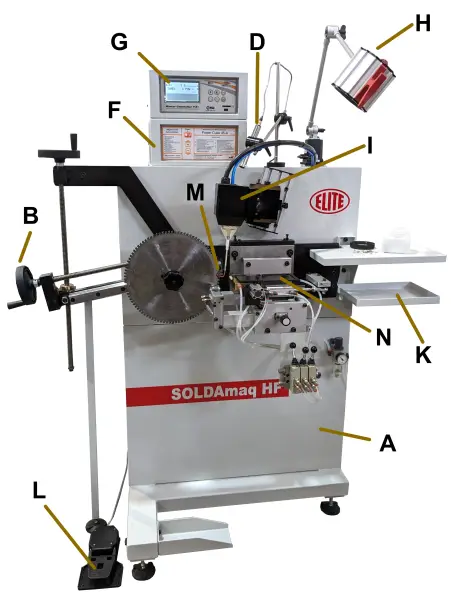

A: Machine base

B: Saw holder support

C: (Reserved)

D: Pyrometer

F: Generator main unit

G: Pyrometer control unit

H: Lamp

I: Inductor coil support head

K: Tool tray

L: Weld activation pedal

M: Inductor coil

N: Tungsten carbide insert magazine

6.START UP

In this section we show you how to operate the ELITE SOLDAmaq HF so that it works.

NOTE: The data that appears in the different images is an example, each type of tool has its recommended data and an expert operator should know them.

DANGER: Never manipulate the control panel buttons while servicing the machine: risk of very serious injuries. It is strongly recommended to turn off and disconnect the machine from the mains when working inside it.

6.1. Power on the machine

The SOLDAmaq HF welder has been designed to weld carbide-tipped circular saw blades with the maximum dimensions described above in the technical characteristics.

The machine is built from welded and machined parts.

Once the machine is connected to the network it can be started. First make sure potentiometer 6 is disconnected.

To start the welder, turn the main switch clockwise.

Make sure the machine is running by checking that the start light is on.

7.WORK OPERATION

The generator has a double function: construction of circular saws with carbide plates and repair of already used saws. Below we will explain both functions.

7.1 WELDING THE TEETH

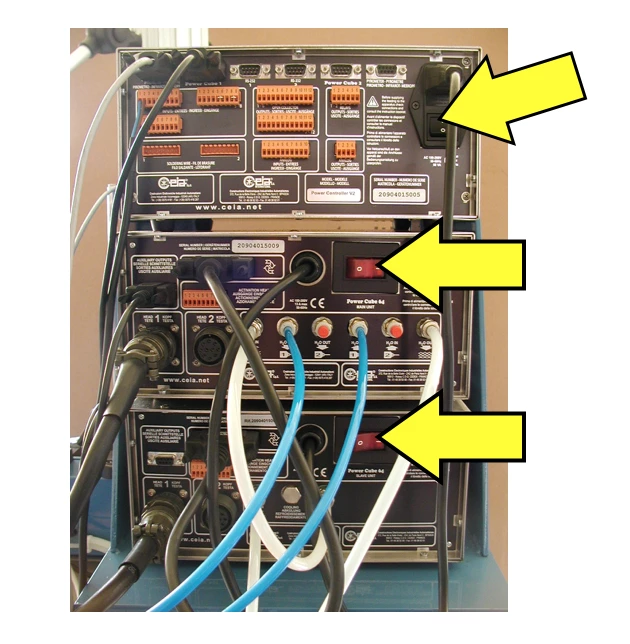

Once all connections have been made (electrical, air, water), the generator can be turned on using the switch (located on the electrical panel at the rear of the machine) by turning it from the OFF position to the ON position.

Check that the generating units (1 to 3 units, depending on version) have the ignition switch activated (E, F, G section 5.4) to do this use the switches on the back of each one.

The cooling system will need to be running, make sure the cooling system is working properly.

ATTENTION: if the cooling circuit does not work, suspend any further operation to avoid serious damage to the machine.

In the case of circular discs to be replated, possible residues must be removed from the plate to be replaced and the tooth seat on the body of the saw must be carefully filed to eliminate any trace of the previous welding.

Before starting it is necessary to establish the type of plates that will be welded. In fact, if they are pre-soldered plates (with the flux and silver already included), you can proceed directly to soldering them, otherwise it is necessary to apply a light layer of brazing alloy (this alloy usually comes in small strips of the same dimensions as the plates to be welded).

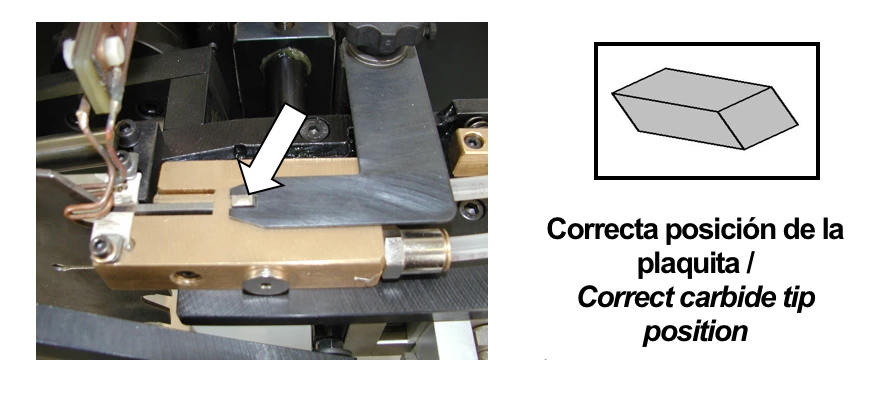

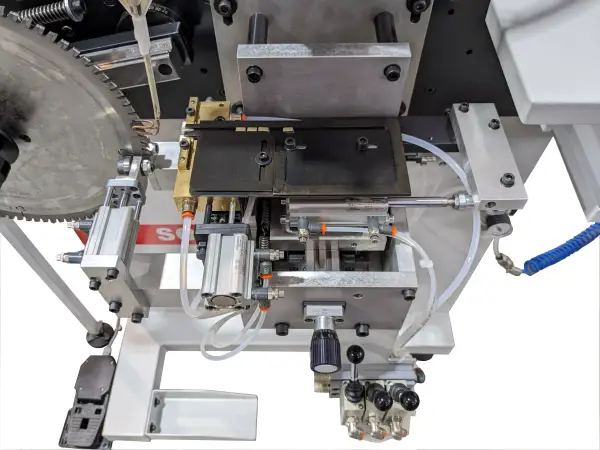

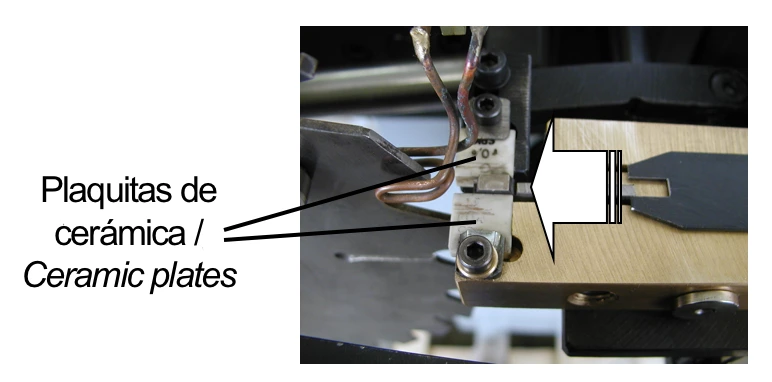

Insert the plates into the cart indicated in the photograph.

Moisten the top surface of the plate with anti-rust liquid: if you are using pre-soldered plates, proceed with soldering. However, if simple plates are used, apply the solder alloy at this point and moisten again with anti-rust liquid.

Using the lever indicated in the following figure, advance the carriage and place the plate in the loading position, paying attention to the inclination of the faces.

Retract the carriage so that the plate is captured by the ceramic plates. At this point, advance the carriage so that the plate is positioned between the induction coil and under the tooth of the circular saw.

Make sure that the inductor coil is well aligned with the plate placed on the carriage and that its spiral does not touch anything on the carriage or the carbide plate. If the coil loop is especially twisted, straighten it manually. The principle of a high frequency generator is to generate an intense oscillating magnetic field that in a short time causes rapid heating of the ferrous masses in its immediate surroundings. The power of the device depends strictly on the distance between the coils and the plate. The best results are obtained by molding the spiral so that its shape follows the shape of the body to be heated as closely as possible. However, remember that the spiral should simply wrap around the body of the saw and the carbide plate without touching it.

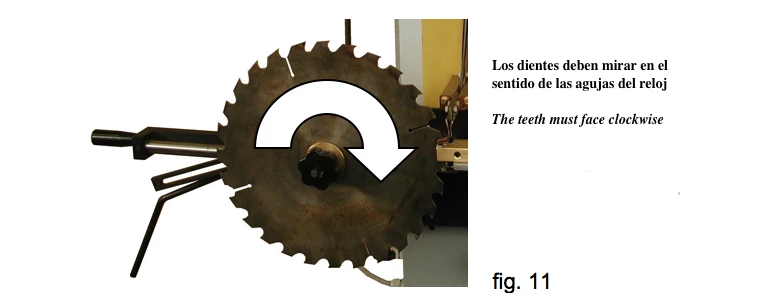

Insert the circular saw into the saw holder. To do this, unscrew the circular knob from the saw holder, insert the circular saw and screw the knob back on. The circular blade should be inserted with the teeth oriented clockwise.

Adjust the position of the circular saw using the adjustment screws and levers, so that the teeth are positioned inside the heating spiral and rest on the plate to be welded placed on the carriage. There are 4 types of adjustment:

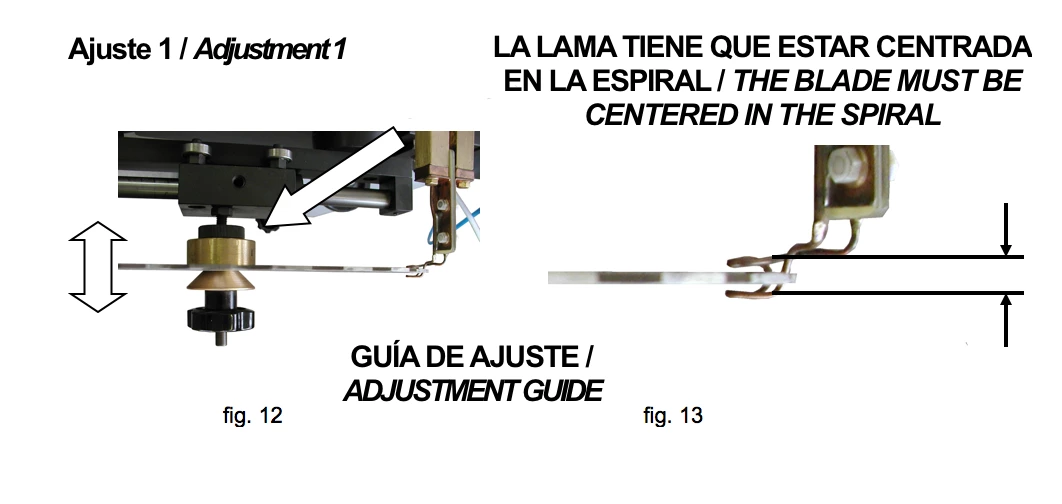

Using the ring nut indicated in the image you can adjust the position of the saw along the rotation pin. The saw must be centered on the heating coil.

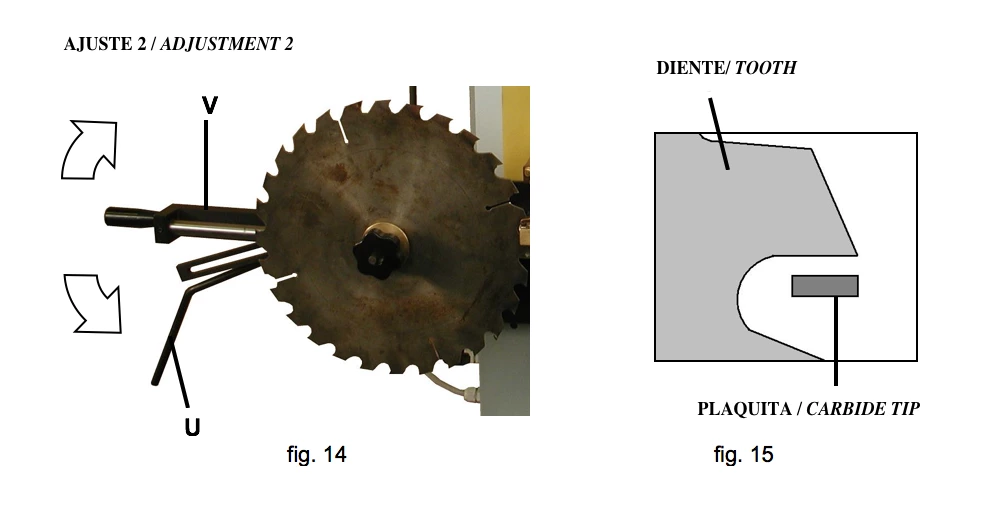

Lift the lever U (fig. 19) to release the saw arm. Hold the V knob (fig. 14) and adjust the inclination of the circular saw so that the front of the tooth to be welded is parallel to the face of the plate (fig. 15). Then lower the U lever to lock the arm in the correct position.

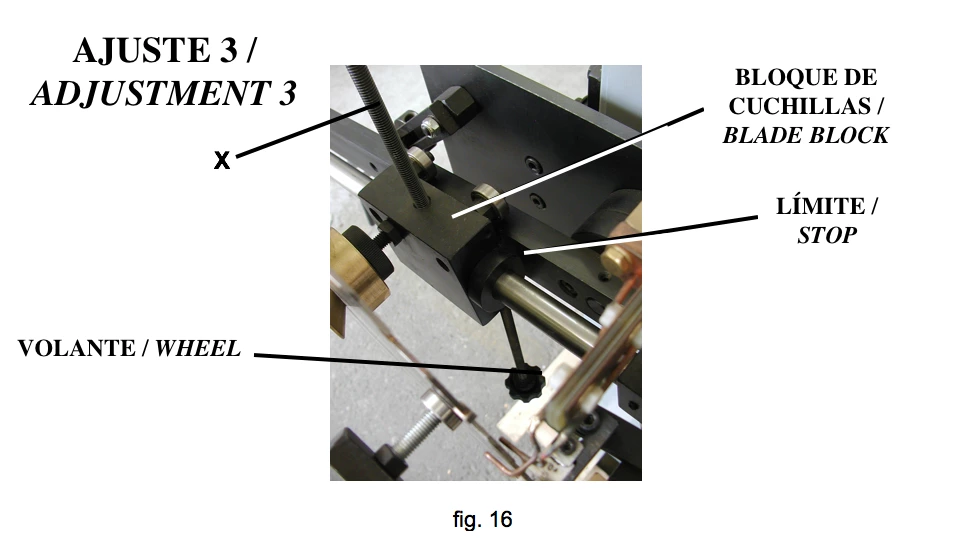

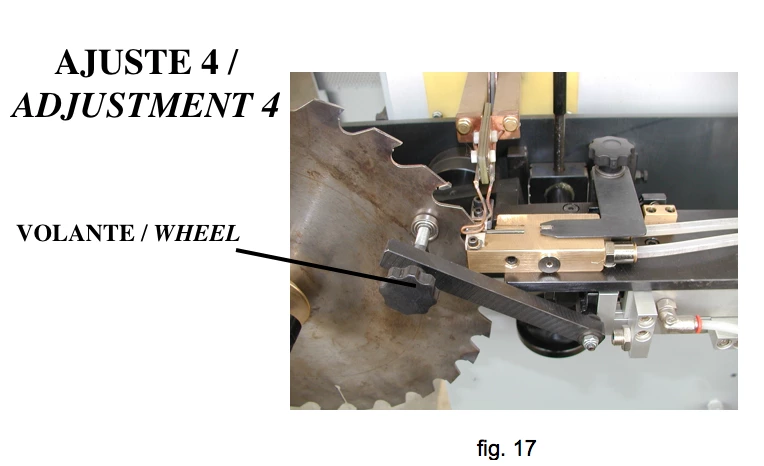

Loosen the handwheel shown in the image to release the spindle stop where the saw holder block is inserted. Unscrew clamping lever Slide the block so that the tooth to be welded is aligned with the spiral coil and plate. Lock the steering wheel and lever.

Moisten both the front of the tooth and the plaque with antioxidant.

Turn the saw holder knob C (section 5.4), press and hold the tooth of the circular blade against the plate.

For working settings, see the attached manuals “Power Cube” and “Power Controller”.

At this point press the L pedal (section 5.4) and keep it pressed.

The generator is heating up. Continue to apply pressure on the saw holder knob C (section 5.4) by turning it clockwise to keep the saw tooth pressed on the plate on the carriage.

Check that heating occurs first on the plate and then on the blade body. Otherwise it means that the turns of the inductor coil are too far from the plate (stop soldering and replace the inductor coil).

After welding is completed, release the L pedal.

At this point retract the carriage and proceed to weld the following teeth.

8.MAINTENANCE

8.1.Preventive maintenance

Maintenance of SOLDAmaq HF welders is very simple. For proper and long-lasting operation of the generator, carefully follow the following precautions.

- Clean the electrodes every time after welding, either with compressed air or with a cloth. They should only be wiped lightly, without any cleaning additives. This will greatly extend the useful life of the electrodes due to wear due to friction with the welding remains.

- If there are machines that produce ferrous dust near the generator, it is essential to clean the carriage block and coil with compressed air and a cloth.

- Periodically check the coolant level inside the cooling circuit tank and, if necessary, refill. Replace the fluid periodically (ONLY RADIATOR COOLANT SHOULD BE USED).

- Ceramic vise plates are subject to wear. Therefore, it is necessary to replace them after a long period of use. The same goes for the plate support.

Verify that the welding input voltage is correct and does not present oscillations.

In case of damage, replace damaged parts with new ones.

Use the equipment only in dry environments. The temperature must be between 5 and 40ºC. A relative humidity greater than 90%, as well as a saline environment, would cause premature corrosion of the machine.

9.ACCESSORIES AND CONSUMABLES

10.WARRANTY

All our machines are tested before being shipped. However, there may always be defects that are not observable at first glance.

Our machines are guaranteed against manufacturing or material defects under normal conditions of use and maintenance.

The term of this guarantee is 12 months from the date of purchase and consists of the replacement of defective material.

The warranty will be automatically canceled in the event of modification beyond our company's control. Or in obvious cases of misuse of the machine.

The warranty does not include parts subject to normal wear and tear due to use such as skates, lubrication cartridge, abrasives, etc.

11.DOWNLOAD MANUAL

EN - User Manual SOLDAmaq HF.pdf

12.FAQ

Question nr1

Answer no. 1