1.FIRST STEPS

Congratulations on your purchase of the ELITE model B 70 drill and countersink sharpening machine.

Please read this guide before you begin.

The ELITE model B 70 is a drill and countersink sharpening machine. It can sharpen drill bits from ø3 a ø 70 mm

This manual introduces you to the main functions of the sharpening machine in order to avoid risks to your health or that may cause a breakdown or premature wear of the machine.

If you have any questions, please contact us directly or one of our authorized distributors

Informative Note: The use described in the manual for this sharpening machine may present some variations in use since our machinery is subject to possible construction modifications, depending on the incorporation of technological advances in our sharpening equipment.

2. SECURITY

2.1.Safety rules

Carefully observe and apply the following safety rules, non-observance of these rules may cause personal injury or damage to the machine itself.

The installation and maintenance of the machine described in this manual must be carried out only by operators who are familiar with its operation and have sufficient technical knowledge.

The ELITE model B 70 drill and countersink sharpening machine has been designed for sharpen drill bits from ø3 a ø 70 mm. excluding any other type of operation.

DANGER HIGH VOLTAGE

DANGER OF ACCIDENT

DANGER DUE TO SPARK PROJECTION

WEAR PROTECTIVE SHOES

DANGER FROM SHARP TOOLS

USE HEARING PROTECTORS

These warnings do not include all possible risks that could be caused by improper use of the machine. Therefore, the operator must proceed with prudence and observing the rules.

2.2.Use and preservation of the instruction manual

This instruction manual must be read and understood by all personnel who come into contact with the machine.

This guide is for:

- Indicate the correct use of the machine according to the type of work to be carried out.

- Provide the necessary instructions for the transport, adjustment and maintenance of the machine.

- Facilitate the order of spare parts and risk information.

Limits of use of the manual:

The machine is intended for professional use and therefore the experience of the operator is necessary and of vital importance.

Importance and conservation of the manual:

This manual must be considered an integral part of the machine and must therefore remain with it until the end of its use.

Additional information and clarifications:

The user, owner or maintenance person can contact the manufacturer to request any additional information on the use of the machine and the possible modalities of maintenance and repair intervention.

Expiration of responsibility:

The manufacturer is considered exempt from any responsibility in case of:

- Improper use of the machine

- Use of the machine by untrained persons

- Serious failures in scheduled maintenance

- Unauthorized interventions or modifications

- Use of non-original spare parts.

2.3.Declaration of conformity

The company hereby:

Elite Sharpening Machines, SLU

Joan Oró, 27

ES-08635 Sant Esteve Sesrovires

Declares that the product indicated below, based on its conception and construction, as well as the version put on the market by our company, complies with the mandatory basic health and safety requirements of the CE directive.

This declaration loses its validity in the event of unauthorized modifications to the product.

Product name: ELITE B 70

Product type: drill and countersink sharpening machine.

Serial number.: __

EC Directive Competences:

- EC Machinery Directive (2006/42/EC)

- European directive on electromagnetic compatibility (2014/30/EU)

- The protection purposes of the CE low voltage directive (2006/95/CE) were fulfilled according to annex I, nr. 1.5.1 of the machinery directive 2006/42/EC

The technical documentation was compiled by legal representative of the documentation:

Sergi Valls Gramunt

Joan Oró, 27

ES-08635 Sant Esteve Sesrovires

Date / manufacturer - Signature: __

Signatory data: Sergi Valls Gramunt, manager

3.TECHNICAL DATA

In the following information table, find the list of technical specifications of the sharpener described in this manual.

| TECHNICAL DATA | ELITE B 70 |

|---|---|

| Sharpening capacity | From ø3 to ø70 mm (0.12" to 2.75"). Optional up to ø70 mm (2.75") |

| Type of drills | 2-, 3- and 4-blade drills for wood or steel, right and left |

| Connection voltage | 200 / 1Ph |

Types of drill bits you can sharpen

4. TRANSPORT

The ELITE B 70 sharpening machine is delivered packed in a wooden box.

During all transport and transfer, the machine must be kept in its original vertical position, any variation in this position may result in the loss of the warranty.

| AVAILABLE VERSIONS | ||

|---|---|---|

| Model | Packaging size | Gross weight |

| B 70 | 800 x 600 x 750 mm. | 80 Kg |

4.1.Unpacking and assembly instructions

Take special care when lifting the load: The load may not be centered!

To lift or move the load, use a forklift with blades long enough to support the machine, taking into account the width and depth of the machine when calculating the weights to be lifted.

To unpack, remove the top panel and any wooden blocking pieces.

The machine is supported by wooden supports bolted to the box. Remove these before attempting to move it.

Once the machine is in its final location, you can remove the protective film and other protection from the components that hold and prevent the load from moving.

5.INSTALLATION

5.1.Machine placement

Before any work, make sure that the machine is well aligned and does not oscillate at any of its ends, in which case it must be shod to prevent movement. For its correct leveling it is necessary to use a leveling tool. This control must be carried out both longitudinally and transversally.

A poor leveling of the machine can cause unwanted vibrations and premature wear of the linear guides.

ATTENTION: The machine must not be used under any circumstances by unqualified or unauthorized personnel.

5.2.Electrical connection

Please note: before connecting the machine, remove any protection that may be present on the machine to protect the components during transport.

The ELITE B 70 sharpening machine must be connected strictly to the voltage indicated on the machine order and on the machine itself. Connection to a voltage other than that indicated may cause a breakdown in the machine and represents a risk to persons using the machine.

For connection to the mains, the machine requires 1 Ph.

This installation must be carried out by qualified technical personnel and checked with a voltage meter before turning on the machine.

It is absolutely essential that the section of the connection cable is the required one, that the machine has a dedicated socket protected against overloads and that it is as close as possible to the power outlet.

We decline any responsibility for a poorly made connection.

Once the connection has been made and checked, turn the main ON/OFF switch to the ON position.

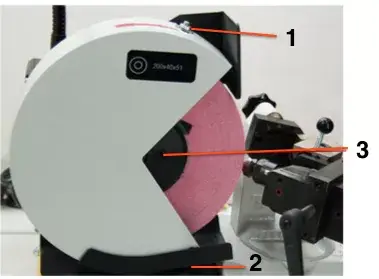

5.3.Main components of the machine

- LED illuminated optical lens (optional)

- Grinding wheel guard

- Grinding wheel

- Cam for clamping the eccentric

- Clamping lever for prism

- Clamping prism

- Prism holder with scale.

- Prism clamping bracket

- Dust extraction nozzle

- Support block (with clamping lever)

- Tip angle adjustment

- Prism feed

- Support plate with fixing slots A1, A, B, C

- Motor, 230 V, 50 Hz

- Main switch

- Star-shaped fixing knob

- Continuous rake angle adjustment

- Clamping screw for rake angle adjustment

- Motor feed

- Clamping lever for support block

- Adjusting screws for roller bearing slide

5.4.Accessories

MT1, MT2, MT3 cone tool holder

Diamond drill bit

Diamond drill bit holder

Depth stop with magnet

Drill bit holder ø40-60 mm.

Useful for sharpening countersinks

Optical lens

Dust extraction nozzle

6. START-UP

This section shows you how to operate the ELITE B 70 so that it works.

NOTE: The data shown in the different images are for example purposes only, each type of tool has its recommended data and an experienced operator must know them.

DANGER: never manipulate the buttons on the control panel while performing maintenance on the machine: risk of very serious injury. It is strongly recommended to switch off and disconnect the machine from the mains when working inside it.

6.1. Switching on the machine

After switching on, a warning light on the control panel lights up. This lamp indicates that the configuration process can be started

6.1.2. Electrical connection

The ELITE B 70 sharpening machine must be strictly connected to the voltage indicated on the machine order and on the machine itself. Connection to a voltage other than that indicated may cause a breakdown in the machine and represents a risk for the people using it.

This installation must be carried out by qualified technical personnel and verified with a voltmeter before switching on the machine.

It is absolutely essential that the section of the connection cable is the required one, that the machine has a specific power outlet and is protected against overloads and shunts, and that it is as close as possible to the power outlet.

We reject any responsibility for a bad connection.

Once the connection has been made and checked, turn the main ON / OFF switch to the ON position.

ELITE Sharpening Machines, rejects all responsibility for a bad connection, which in addition to causing a malfunction of the machine can harm people, animals or objects.

7. OPERATION OF THE WORK

7.1. General operation

7.2. Use

For drill bits from 3 to 20 mm. use the support with the inner jaws. For drill bits from 20 to 40 mm. remove the inner jaws.

To remove them, remove the 4 pins with a 2.5 mm wrench.

To fix the jaws: place them on the support so that the graduated line is aligned with the external marks.

The numbers on the jaws will not be visible. Gently clamp the pins, without over-tightening.

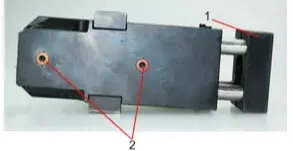

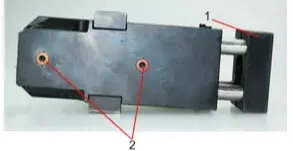

7.3. Clamping and aligning right-hand twist drills

Loosen clamping screw 2 and pull pin 1 out as far as it will go. Clamp again, depending on the diameter, allowing the drill to protrude from the holder.

3-35 mm drills: with the cut tight to the holder.

35-40 mm drills: fitted to the end of the pin protruding from the holder.

Next, align the parallel cut to the right line marked on the chuck

To achieve parallelism on small drills, it is suggested to fix a second drill of the same diameter on the back of the first.

For larger diameter drills, use the extension of the support for the cylindrical part

Remove pin 1 and fix with the screw.

For broken drills, first plan the front.

7.4 Right-hand drill alignment

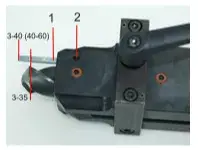

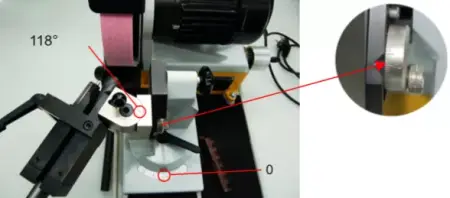

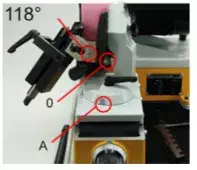

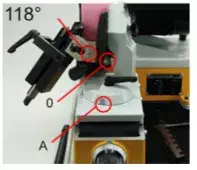

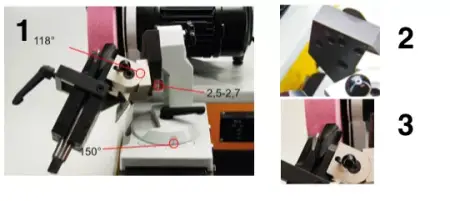

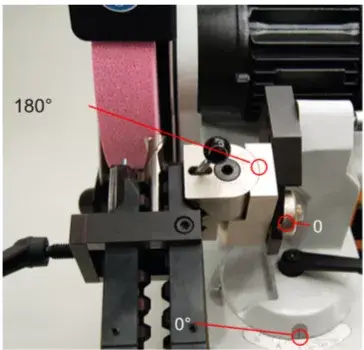

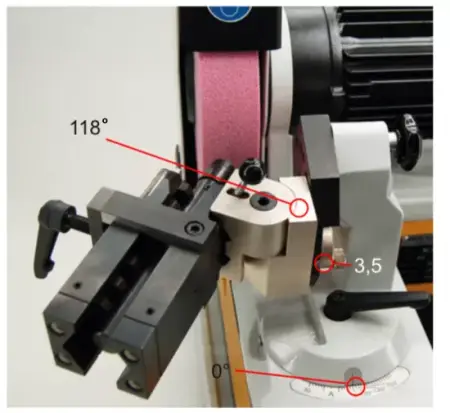

Set the prism to 118º and the support to the 0 value on the scale. To adjust the clearance angle, open the clamping screw (B) and adjust with the eccentric by closing the pin to the value indicated below. The lower the value on the scale, the lower the clearance angle. Loosen the star knob.

- A: Star knob

- B: Clamping screw

- C: Clearance angle adjustment

| Clearance angle | |

|---|---|

| Drill bit, Ø | Scale degree |

| 3 - 40 | 1.5 - 2.5 |

| 40 - 60 | 2.0 - 3.0 |

Next start the motor and rotate the prism with the drill bit by carefully moving the guide forward towards the grinding wheel. Note the position on the scale and back. Open the cam and rotate the prism 180º. Finally, check the alignment by making sure that the cutting angle is parallel to the graduated line.

7.5 Core emptying of twist drills

To core empty, without removing the drill from the clamping prism, we must set the clearance angle to 0 and fix the prism holder with the star knob in hole C.

Move the grinding wheel with the motor to the right. We open the clamp on the prism and adjust it to the line “A”

Now we can start sharpening approximately 1/10 of the diameter of the drill bit using or the left side of the grinding wheel, on the inside of the cutting angle. For correct positioning we must turn the support prism and the feed motor. The width of the cross cut should be approximately 1 mm. For a drill bit with a diameter of 10 mm. To make both sides we must turn the support prism and repeat the process.

7.6 Sharpening left-hand drill bits

We must insert the drill bit outside the clamping prism depending on the diameter (even for right-hand drill bits)

Align the cutting angle to the line, as shown in the following photo

To correctly set the rake angle, release the infinite adjustment of the cutting angle 1 and press on 2. Line 1 is for right-hand drill bits and line 2 is for left-hand drill bits.

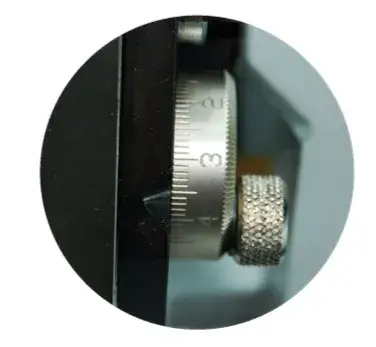

For left-hand drill bit sharpening, the higher the number, the lower the clearance angle.

| Clearance angle | |

|---|---|

| Drill bit, Ø | Scale degree |

| 3 to 14 | 3.3 - 3.9 |

| 15 to 40 | 2.7 - 3.3 |

| 40 to 60 | 2.2 - 2.8 |

For sharpening the core of the drill bit, use position 1, turn the clamping prism to position “A” and secure the star knob in hole A1 (see figure below). The rake angle setting determines how far we should go into the core (approx. 1/10 of the diameter)

| Table 3 | |

|---|---|

| Drilling, Ø | Scale degree |

| 3 - 20 | 2 - 2.6 |

| 21 - 40 | 2.7 - 3.3 |

| 41- 60 | 3.2 - 3.8 |

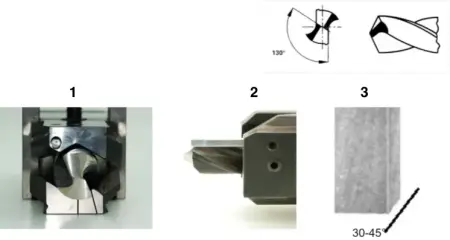

7.7 Cross-cut or faceted drill bits

Main cut:

The drill bit is aligned like a right-cut spiral drill bit with the right graduation mark (1).

For the cross-facet shape, always align the drill with the full length of the pin (2). Now sharpen the main cutting edge in the same way on both sides as described in section 7.4

To thin the band, line the right edge of the grinding wheel with approx. 30° 45° by hand (3).

After finishing the grinding procedure, let the drill clamp into the prism. Set the clearance angle to 2.5 - 2.7 (photo 1). Secure the prism with the Phillips screw in hole C (photo 2). Turn the upper angle to approx. 150°. Now move with the grinding wheel, starting from the outer edge of the drill to the centre of the chisel edge of the drill (photo 3).

Look at the feed mark and move away from the wheel. Invert the prism 180°. Now repeat the last steps and advance to the indicated feed mark

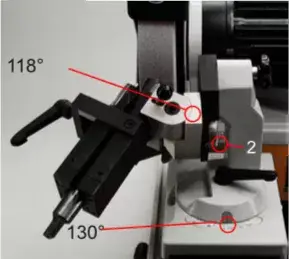

7.8 Carbide drill bits - for stone

Sharpen only with diamond or silicone wheels. Insert the drill bit into the holder leaving approximately 30 mm outside the holder. Align the cutting angle parallel to the graduated straight line (position 2 in the following figure)

Set the holder to 118º and the base adjustment to 130º. Graduated rake angle to 2 (depending on the type of drill bit, more or less). Fit the star knob into hole B. Using the feed, sharpen from the outside to the inside of the plate. Rotate the holder 180º and repeat the process.

To correct the main cutting angle, keep the bit fixed inside the holder, just fix the unit in hole A1. Repeat the above process

7.9 Sharpening metal drill bits

Insert the bit into the holder leaving 40 mm. out of the holder and align one of the cuts to line 2

Attach the diamond cutter to the holder and diamond the inside of the wheel at 60º (see next photo).

Adjust the clamping prism to 180º, rake angle as needed. Adjust the star knob screw in hole B.

With the motor moving forward, go from left to right turning the prism. Rotate the holder and sharpen the second face.

Sharpening the center point:

Leave the drill bit fixed in the holder. Set the holder to 118º and the base adjustment between -30 and -A. Adjust the rake angle between 2 and 3.5 and fix the star knob in hole C. Moving the motor and the drill bit feed, move in a criss-cross fashion to achieve the pyramid shape. Note the positions on both scales (motor and prism feed) and repeat on both sides.

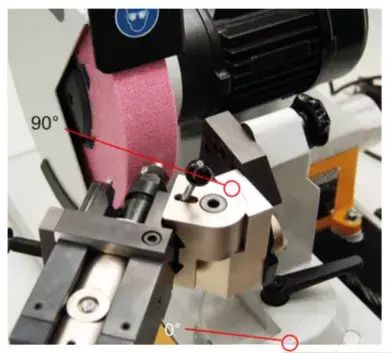

7.10 Sharpening drill bits for 90º control

Insert the drill bit into the holder leaving the 15 mm out and position the cutting angle parallel to the drill bit sharpening setting (position 3).

Set the holder to 90º and the clearance angle to 3.2 (approx.) Move the feed with the oscillation and sharpen one side. Rotate the holder and sharpen the second side.

7.11 Sharpening two-cut 118º double-cut drills

First step: Set the holder to 118º on the scale. The process is the same as for right-hand drills.

Step 2: Adjust as in step 1 and bring the second cut towards the right side of the wheel at a right angle to the wheel. Rake angle depending on your needs.

7.12 Sharpening bi-diameter drill bits at 90º

Step 1: Same as for a standard right-hand drill bit.

Step 2: For this we have to hollow out the right side of the wheel from the outside to the middle. Set the holder to 118º, rake angle to 0. Set the star knob in position A. Using the feed, sharpen from the outside to the inside and back off once finished. Turn the holder to repeat the other cut.

7.13 Sharpening reamers

Empty the grinding wheel as indicated in the previous section.

Set the tool in the holder leaving about 35 mm. outside the holder and align a cut parallel to the marked straight line. Use the magnetic brake (see section 5.4 Accessories). Set the rake angle to 0 and position the star knob at A. Sharpen from the inside out using the motor feed. Back off and align the next cut.

Do not change the holder position. For back sharpening set the star knob at B and repeat the sharpening process described above.

7.14 Sharpening two-cut cutters

Set the cutter and align one of the cuts parallel to the positioning straight line.

For small cutters place another cutter of the same diameter behind the first.

For sharpening the main cut, set the holder to 180º, the base to 0 or 1-2 or right in the middle. Set the rake angle to 0. The star knob to position A

For sharpening the rake angle: set the star knob to B and repeat the process as for the main cut.

For cutters with more than 2 cuts (max. 4) you will need the optional magnetic depth adjustment accessory (see section 5.4 Accessories).

7.15 Sharpening the grinding wheel

Attach the rotating diamond cutter to the base set at 118º. Clamp with the star knob set to A. Set the rake angle to 3.5 and the clamping jaw support to 0.

Move the prism feed towards the grinding wheel until the diamond gently touches the grinding wheel and starts to rotate. Now move the motor feed to the left or right until the grinding wheel is clean and sharp again.

Attention: Apply load gently and carefully (maximum 2-3 scale lines).

7.16 Special accessories

7.16.1 Sharpening countersinks

For sharpening countersinks, the optional accessory for this type of tool is required: countersink sharpening stand.

First fix the backing plate in hole A. Then set the rake angle to No. 2. This ensures that the imaginary line goes through the centre of the clamping jaw and the centre of the grinding wheel.

The clamping prism must be set at 90º. Now place the countersink in the clamp of the countersink sharpening stand and align the cutting edge as shown in the following photo, on the graduated line.

Move the clamping prism to the stop of the stand and fix the pin for this purpose. Then fix the countersink holder in the clamping prism from 20 to 40 mm. By turning the countersink chuck handwheel clockwise we will give the sharpening load.

The use of a well-sharpened and clean grinding wheel is recommended to prevent the countersink from burning.

Countersink alignment

Basic adjustment of a 3-cut countersink with 10 mm collet + nut

The step cam (optional) is required for sharpening countersinks. The adjustment is made as shown in the following figure (the left is incorrect and the right is correct.

Alignment of the cross-shaped countersinks

Alignment of countersinks

Cam for cross-shaped countersinks (optional)

Adjust the clearance angle to mark No. 2

6/8/10 collets 12 mm. (optional)

Set the star knob in position A

Cam change

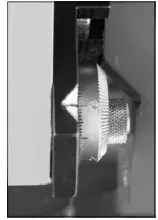

If you need to change the cam on the countersink holder, loosen the threaded pin with a 3mm allen key (see picture)

Place the holder with the flywheel on a flat surface.

Manually press down on the body (against the spring tension).

With the other hand, slide the cam out of the bearing through the top of the body.

The cam is inserted in the reverse order.

Be careful that the pin is mounted in the place where it was removed.

- 1: Draw the cam next to the bearing upside down

- 2: Threaded pin

- 3: Receiving body

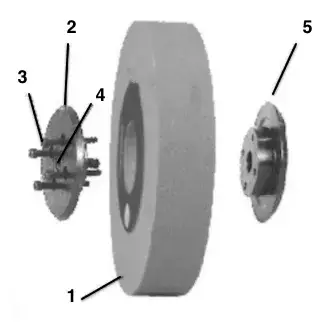

7.17 Mounting the grinding wheel

For the standard grinding wheel: The picture shows the mounting of the grinding wheel with the grinding wheel holder.

Please note that screw no. 4 has a right-hand thread (also for mounting special grinding wheels)

Place the supplied plastic spacers between the holder and the grinding wheel. After mounting the grinding wheel, loosen both flat-head screws with a 10 mm open-end wrench or combination wrench and remove the grinding wheel cover to the left side.

Place the new grinding wheel on the motor shaft and tighten the M8 allen screw. Now remount the grinding wheel in reverse order and check if the grinding wheel cover is mounted correctly.

Never use the B70 sharpener with a grinding wheel cover that is not mounted correctly. Once you have mounted the grinding wheel correctly, you will need to grind it.

Attach the gyroscope to the prism, set the prism holder to 118°, secure it with the fixing screw in hole A. Turn the clearance angle adjustment to position 3.5. The prism rests at 0. Move the prism feed towards the grinding wheel, so that the diamond touches the grinding wheel and starts to rotate. Move the motor feed with the grinding wheel left and right, clean and adjust the grinding wheel.

CAUTION: Feed carefully (only feed 2-3 graduation lines) with the prism feeder.

Special grinding wheels

For 20 mm thick grinding wheels the 20 mm spacer ring must be used.

For 8 mm thick grinding wheels the 32 mm spacer ring must be used.

7.18 Changing the grinding wheel

- 1: Nut 1

- 2: Nut 2

- 3: Allen screw 3. Right-hand screw that is opened by turning it to the left.

!! To change the grinding wheel, disconnect the machine from the mains.

Open the two screws 1 and 2 of the guard with a 10 mm spanner. Remove the guard from the grinding wheel.

Loosen the hexagon screw with a 5 mm allen key. Turn the screw until the grinding wheel can be removed with the grinding wheel holder.

Insert the new grinding wheel onto the motor shaft and tighten the screw again, finally attach the grinding wheel guard. Check that the grinding wheel is correctly mounted.

Never use the machine without the grinding wheel guard installed

7.19. Technical support service

At ELITE we try to satisfy our customers through reliable and easy-to-use products. However, if you experience any problems while using the machine, do not hesitate to contact us as soon as possible directly or through our authorized distributors, who will assist you, if there are any in your country, with greater proximity and professionalism.

We hope that you enjoy this product for many years, please: when the life of the sharpener ends, dispose of it correctly in the necessary facilities for its correct disposal and recycling.

8.1. Preventive maintenance

The ELITE B 70 drill grinder should be cleaned from grinding dust with a soft brush.

Persistent dirt, please clean with usual in trade machine cleaner. After cleaning, please grease all movable parts with some drops of machine oil.

To prevent erosion of the blank parts, also grease with little oil and rug with a soft rag.

Use the equipment only in dry environments. The temperature must be between 5 and 40ºC. Relative humidity greater than 90%, as well as a saline environment, would cause premature corrosion of the machine.

8.2. Spare parts list

- 3-20 mm inner jaws.

- 20-40 mm prism.

- 40-60 mm prism.

- Complete diamond cutter

- Gyroscopic diamond cutter replacement

- Optical lens with neon

- Neon lamp

- 200x40x51 mm corundum wheel. Grit 60 (standard)

- 200x40x51 mm corundum wheel. Grit 100

- 200x40x51 mm corundum wheel. Grit 180

- 200x20x51 mm corundum wheel. Grit 100

- Spacer for 8 mm wheel.

- Grinding wheel holder with cone

- Prism holder

- Clamping for prism holder

- Eccentric pin for prism holder

- Ball bearing for mechanical rotation

- Dust guard protection

- M10 clamping cam for prism 20-40 mm

- Pin for length adjustment on prism

- Motor 400 V. 50 Hz.

- Grinding wheel guard

- Control button with scale

- Trapezoidal spindle TR 12x3 for feed of the load

9. ACCESSORIES AND CONSUMABLES

9.1. Grinding wheels

9.1.1. For sharpening steel drill bits

We recommend using ELITE ref. nr. B70-13. Corundum ø200x40x51 mm.

9.1.2.For sharpening hard metal drill bits.

We recommend using ELITE ref. nr. B70-14. 1A1. D76 C75. Diamond ø200x30x3xø51 mm.

9.1.3.For sharpening HSS drill bits we recommend using ELITE ref. nr. B70-15. 1A1. B76 C75. Bore ø200x30x3xø51 mm.

10. WARRANTY

All our machines are tested before being shipped. However, there may always be defects that are not visible at first glance.

Our machines are guaranteed against manufacturing or material defects under normal conditions of use and maintenance.

The period of this warranty is 12 months from the date of purchase and consists of the replacement of the defective material.

The warranty will be automatically voided in the event of modifications not carried out by our company or in obvious cases of misuse of the machine. The warranty does not include wear parts.

11. DOWNLOAD MANUAL

12. FREQUENTLY ASKED QUESTIONS

Question nr1

Answer no. 1