AUTOMATIC MACHINE FOR SIDE GRINDING WITH DOUBLE WHEEL ON CARBIDE-TIPPED CIRCULAR SAW BLADES FROM ø100 TO ø850 MM. WITH 4 CNC AXIS

HIGHLIGHTS

- Any tooth pitch is possible

- Integrated refrigeration equipment

- Robust and very simple design that allows continuous use of the machine without breakdowns

- Easy to use

- Very compact machine with a wide range of disc diameters: from 100 to 850 mm.

ELITE GBT 850. THE CONCEPT.

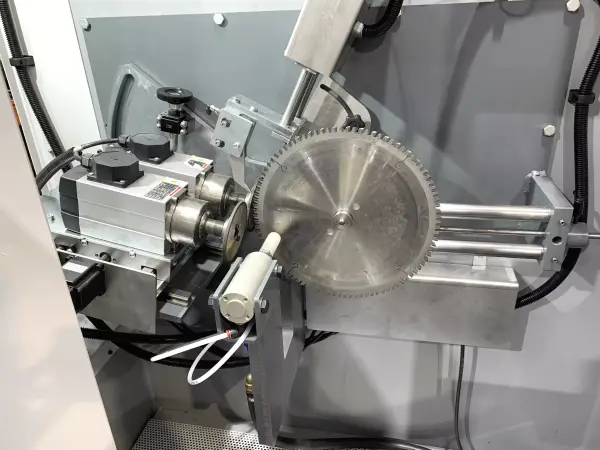

The ELITE model GBT 850 is our automatic dual-side grinding machine for circular saw blades from ø100 to ø850 mm. diameter.

It allow for precise and rapid grinding of tooth flanks to manufacture carbide-tipped circular saw blades or for tip replacements.

It is designed to be automatic without unnecessary additional costs. No complicated extra that can easily break or are expensive to repair.

ELITE GBT 850. HOW IT WORKS

Very simple programming through a guided menu or entering grinding data.

Automatic work by means of 4 CNC axes:

- X: Sharpening path

- Y1: Tangential angle of wheel No. 1

- Y2: Tangential angle of wheel No. 2

- A: Tooth pitch

Fully enclosed cabin for silent operation with a very fast door opening system that guarantees quick mounting of the saw blade and access door for maintenance.

Easy to use control panel

The control panel incorporates a color touch screen. This screen has been designed with a fast and easy-to-use interface that makes it very user-friendly. It is also possible to create or edit a program while the machines is running.

The machine includes a LED cabin light as standard.

Tooth pitch programmable through the software on the control panel.

Control Panel

Grinding wheel rotation speed variable from 5.000 to 9.000 RPM

The direct grinding wheel spindles are adjustable between 5,000 to 9,000 RPM for optimal sharpening quality with minimal grinding wheel wear.

The spindles are driven by a frequency inverter, so you can adjust the grinding wheel speed to the optimal value as well as reduce energy consumption.

Saw diameter

Saw diameter from ø100 mm. up to ø850mm. diameter to grind the flanks of scoring discs or portable machines as well as sawmill saws.

Allows indexing of any type of tooth pitch.

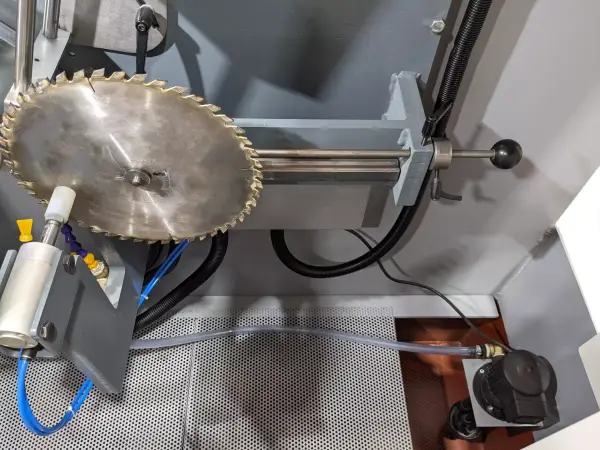

Integrated refrigeration equipment

Machine operates with water-soluble coolant or grinding oil for better sharpening quality and longer grinding wheel life. Integrated coolant system with 220-liter tank and removable grates for easy cleaning.

Machine operates with water-soluble coolant or grinding oil for better sharpening quality and longer grinding wheel life. Integrated coolant system with 220-liter tank and removable grates for easy cleaning.

Easy access and maintenance

At the back of the machine we find the electrical panel at the bottom and the mechanical system at the top, both protected by their corresponding easy-access panel, which also reduces the total space needed for the machine.

ELITE GBT 850. EQUIPMENT INCLUDED

- Grinding wheel holder for sharpening wheels (two units).

- 3 mm. feed pawl

- Lighting of the work area using LED lamp

- Device for sharpening saws of equal diameters

- Machine closed by enclosure.

- Prepared for connection to a machine filtration system or a centralized filtration system.

ELITE GBT 850. SPECIFICATIONS

| TECHNICAL DATA | GBT 850 |

|---|---|

| Saw blade diameter | From ø100 to ø850 mm. (4" to 33.5") |

| Saw blade hole diameter | From ø10 mm. |

| Saw tooth thickness | Up to 14mm. |

| Saw body thickness | Up to 8mm. |

| Tooth pitch | From 1 to 125 mm. |

| Grinding wheel diameter | ø100 mm. (2 units) |

| Grinding wheel hole diameter | ø20 mm. |

| Automation | Using 4 CNC axes (X, Y1, Y2, A) |

| Manual axles | B, Z |

| Saw holding | By pneumatic clamping |

| Motor wheel | 0.75 kW x 2 units |

| Grinding wheel speed | Adjustable from 5000 to 9000 RPM |

| Machine dimensions | 1650 x 1200 x 1900mm. |

| Machine weight | 740 Kg. |

| FLANK GRINDING | |

| Grinding path | Up to 40 mm. (1,57") |

| Rake angle | From -15º to +30º |

| Radial cutting angle | From +5º to +6º |

| Tangential cutting angle | From 0º to 8º |

| REFRIGERATION EQUIPMENT | |

| Tank capacity | 220 liters |

| Coolant flow rate | Up to 40 liters/minute |

TECHNICAL REQUIREMENTS

A 6 bar air connection is required. Connection voltage: 220/400V 2Ph 50/60Hz

Required connection power: 2.5 kW

RECOMMENDED OPTIONAL ACCESSORIES

Saw holders for incisors and for discs, and centering rings in various sizes

For better sharpening quality, it is recommended to equip the machine with the filtration system ELITE FILTRAmaq UNO. Filtration down to 2 µm.

DOWNLOAD LEAFLET

VIEW USER MANUAL

COMPLETE SOLUTION FOR THE REPAIR OF CIRCULAR SAWS

Together with the tungsten carbide plate welder ELITE model SOLDAmaq 1200, you can carry out the complete repair of your circular saws in three steps:

- Desoldering of damaged teeth in the welder SOLDAmaq 1200

- Welding of the new carbide plates in the welder SOLDAmaq 1200

- Grinding of the side flanks on the GBT 850/GBT 851

And we already have the saw repaired!

REQUEST INFORMATION

MACHINES COMPARISONS AT A GLANCE

| MODEL | TOP GRINDING | FACE GRINDING | BACK OFF GRINDING | SIDES GRINDING |

|---|---|---|---|---|

| AVB 850 | All tooth shapes | All tooth shapes | No | No |

| AVB 750 | All tooth shapes | All tooth shapes | No | No |

| SVG 850 | All tooth shapes | Flat teeth | No | No |

| SVG 750 | All tooth shapes | Flat teeth | No | No |

| MVB 850 | Flat teeth | Flat teeth | Yes | No |

| MVB 750 | No | No | Yes | No |

| MVB 670 | Chipbreaker slots | No | No | No |

| MVB 650 | No | Hollow face | No | No |

| GBT 851 | No | No | No | Yes both sides at same time |

| GBT 850 | No | No | No | Yes both sides at same time |

| GBT 750 | No | No | No | Yes: One side at a time |