AUTOMATIC CIRCULAR BLADE GRINDING MACHINE WITH DOUBLE WHEEL FROM ø100 TO ø700 MM.

HIGHLIGHTS

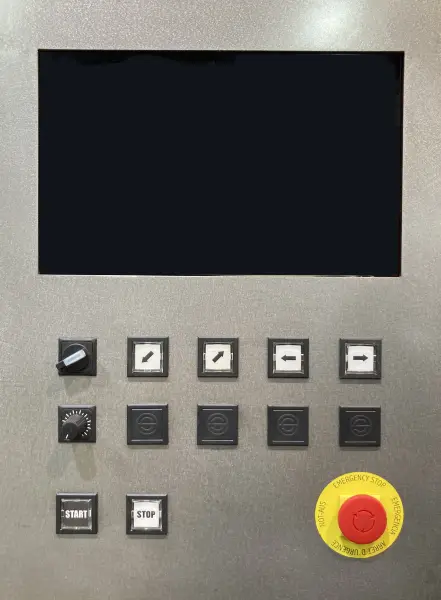

- EASY TO USE: Control panel with on-screen guided instructions

- Grinding cycle with coolant

- 3 CNC axis for automatic work programmable from the control panel

- Circular knife rotation speed adjustable without steps.

- Programmable grinding phases: Roughing, finishing, polishing.

- Full enclosure for a safe operation

ELITE JVC 800. MACHINE BASIS.

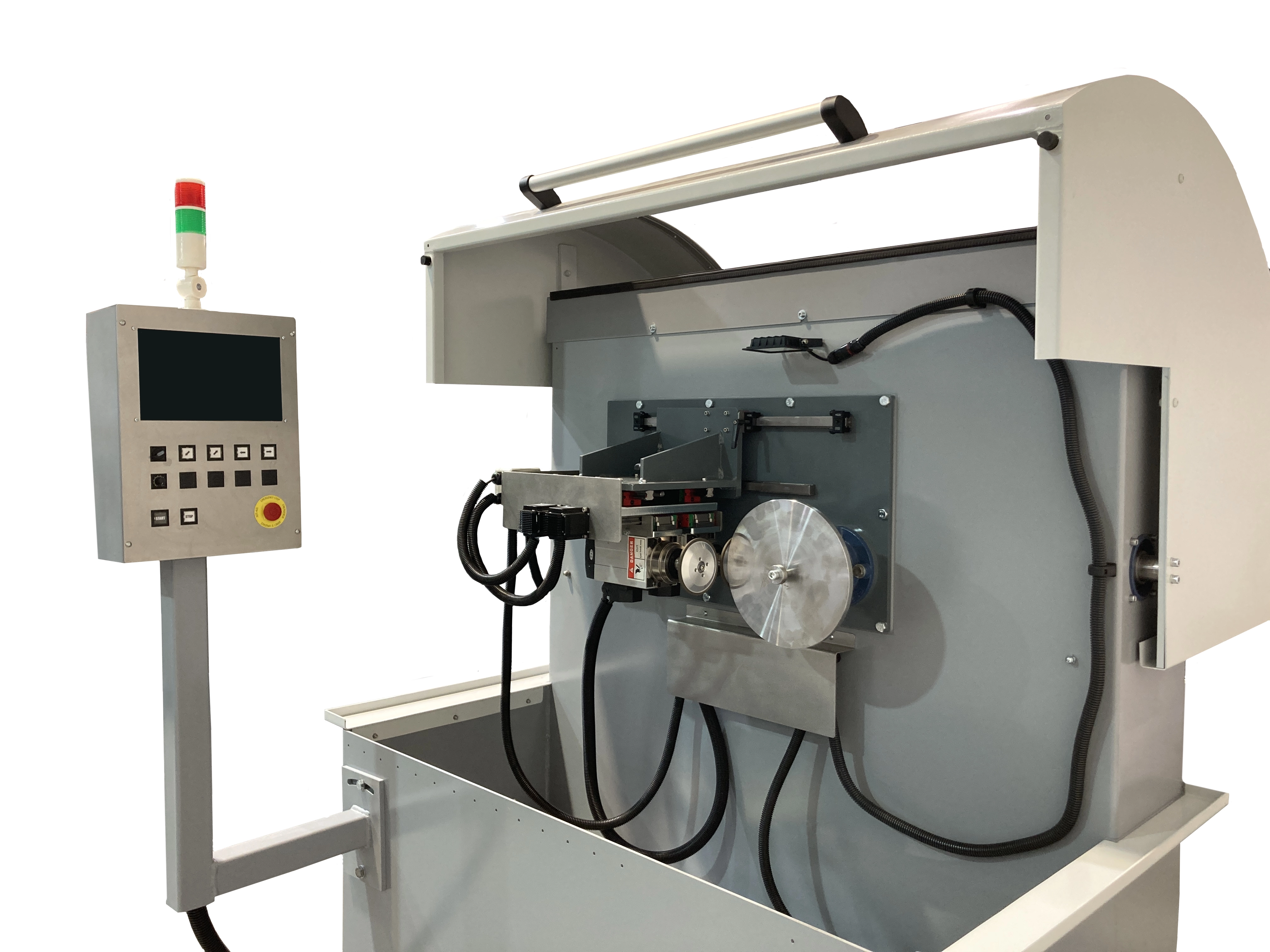

The ELITE model JVC 800 is our sharpening machine for circular knives with high quality finishes and the best working times.

With 3 CNC axis it allows the sharpening of 2 cutting angles at the same time.

ELITE JVC 800. HOW IT WORKS

Easy to use control panel

All the functions of the buttons are explained in the buttons with illustrations. And every button is intended to do a single task. So you know what to expect from a button press.

The control panel with LCD screen allows the programming of the machine, among the programmable values are:

- Roughing phase:

- Infeed

- Total amount to be grinded

- Circular knive rotation speed

- Finishing phase

- Infeed

- Total amount to be grinded

- Circular knive rotation speed

- Fine-finishing phase:

- Time of the fine-finishing operation

- Circular knive rotation speed

Grinding wheel rotation speed variable from 5.000 to 9.000 RPM

Available as an standard feature

Program for equal diameters included as standard

You can produce circular saw blades at the same diameter..

Integrated cooling equipment

Machine operates with water-soluble coolant or grinding oil for better sharpening quality and longer grinding wheel life.

Integrated coolant system with 220-liter tank and removable grates for easy cleaning.

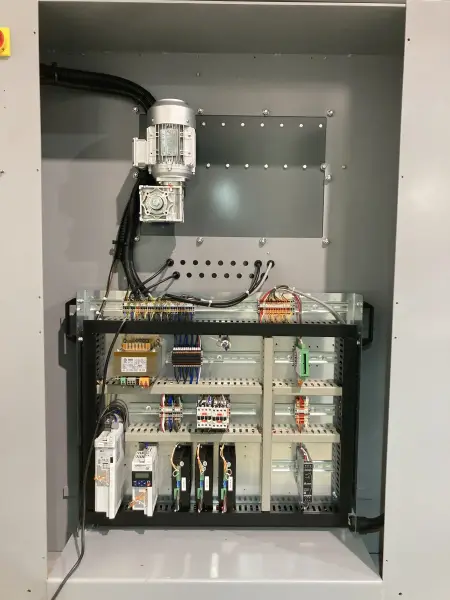

Easy access and maintenance

At the back of the machine we find the electrical panel at the bottom and the mechanical system at the top, both protected by their corresponding easy-access panel, which also reduces the total space needed for the machine.

ELITE JVC 800. EQUIPMENT INCLUDED

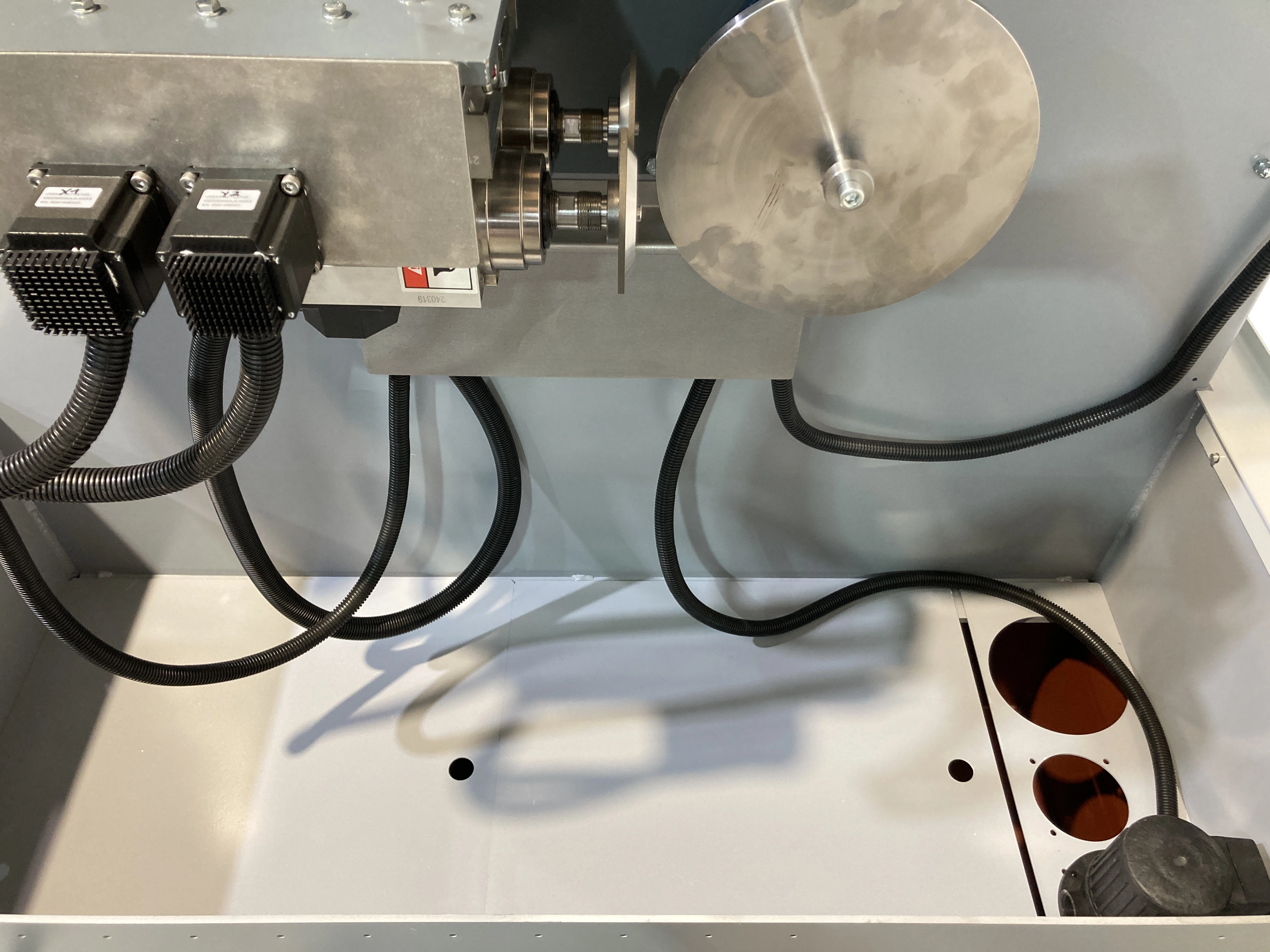

- 3 CNC axes (X, Y1, Y2)

- Program for sharpening circular blades with equal diameters.

- Machine with full enclosure

- Sharpening cycle programming (roughing, finishing, polishing) via LCD screen

- Prepared for connection to a machine filtration system or a centralized filtration system.

ELITE JVC 800. SPECIFICATIONS

| TECHNICAL DATA | JVC 800 |

|---|---|

| Blade diameter | from 100 to 700 mm (4" to 27.5") |

| Blade hole diameter | From 10mm. |

| Automatic axis | 3 CNC |

| Manual axis | 1 |

| Grinding wheel motor | 2x 0.75 kW (2x 1 HP) |

| Blade holder speed | Programmable for roughing, finishing and polishing. |

| Blade rotation speed | 10 - 200 RPM |

| Circular blade angle | +45º to - 45º |

| Number of blade angles sharpened simultaneously | 2 |

| Screen | 10" color touch |

| Sharpening cycle programming | Roughing, finishing and polishing. |

| Number of grinding wheels | 2 |

| Grinding wheel rotation speed | Adjustable from 5000 to 9000 RPM |

| Diameter of the grinding wheel for sharpening | ø100 mm. |

| Grinding wheel hole diameter | ø20 mm. |

| Cooling tank capacity | 220 L. |

| Coolant flow rate | up to 60 liters/minute |

| Machine dimensions | 1430 x 1285 x 1820mm. |

| Machine weight | 650 kg |

TECHNICAL REQUIREMENTS

Connection voltage: 220V/240V 1Ph 50/60HzHz.

Required connection power: 2.5 kW

RECOMMENDED OPTIONAL ACCESSORIES

For better sharpening quality, it is recommended to equip the machine with the filtration system ELITE FILTRAmaq UNO. Filtration down to 2 µm.

DOWNLOAD LEAFLET

REQUEST INFORMATION

MACHINES COMPARISONS AT A GLANCE

| MODEL | Circular knife diameter | Cutting angle | Nr. of bevel angles sharpened at the same time | Nr. of grinding wheels |

|---|---|---|---|---|

| JVC 700 | 30 a 800 mm. | 0º a 100º | 1 | 1 |

| JVC 800 | 100 a 700 mm. | -45º a 45º | 2 | 2 |